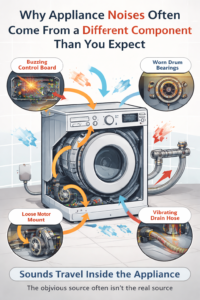

Appliance noises are easy to misinterpret. A rattle, hum, or grinding sound often seems to come from the most obvious moving part. Because the noise is heard during operation, it feels logical to blame the component that appears most active. It is often worth slowing down here, because the perceived source of a sound is frequently not the actual one.

Understanding why noises travel and shift inside appliances can help explain why initial assumptions are so often wrong. Pausing before deciding where a sound originates can prevent unnecessary focus on the wrong component.

Why the Loudest Part Is Rarely the Source

Human hearing tends to localize sound based on vibration and timing, not on internal structure. In appliances, rigid frames and enclosed spaces allow vibrations to travel easily. A noise generated in one area may resonate elsewhere, making a different component seem responsible. This is similar to cases where a washing machine problem isn’t the washer at all, but another connected system creating misleading symptoms.

This effect is especially strong in metal housings and shared mounts. What sounds like a motor issue may originate from a nearby support or connection. Slowing down to question the most obvious source can reduce early misjudgment.

The loudest point is often where sound exits, not where it begins.

How Vibration Redirects Sound

Appliances are built as interconnected systems. When one part vibrates, that energy can move through fasteners, panels, or internal frames. These structures can amplify or reshape the sound.

As a result, a minor issue in one component may produce a noticeable noise in another location. This redirection can make diagnosis confusing. Pausing to consider how vibration moves can help separate cause from effect.

Sound follows structure, not intuition.

Why Moving Parts Get Blamed First

Components that visibly move tend to attract blame. Drums, fans, or rotating arms feel like natural suspects when noise appears. This bias is understandable, but it can be misleading.

Non-moving or less visible parts, such as mounts or housings, often play a larger role in noise creation than expected. Slowing down to include these quieter contributors can broaden understanding.

Movement draws attention, but stillness can transmit noise.

How Timing Can Mislead Diagnosis

Noises often appear during specific phases of operation. This timing can reinforce assumptions about which component is active at that moment. However, internal stress or load changes can affect multiple parts simultaneously.

A sound that begins during a spin or heating phase may actually be triggered by pressure elsewhere. Pausing before linking timing directly to a single component can help avoid narrow conclusions.

Timing explains when a sound appears, not always why.

Why Similar Noises Can Have Different Origins

Two appliances can produce similar sounds for very different reasons. A hum may indicate electrical strain in one case and mechanical vibration in another. Relying on sound alone can blur these distinctions.

This similarity is why online descriptions often fail to clarify the true cause. Slowing down and resisting pattern-matching can prevent false confidence.

Sound quality is a clue, not a diagnosis.

How Structural Wear Changes Sound Paths

As appliances age, their internal structure changes. Fasteners loosen slightly, materials fatigue, and contact points shift. These changes alter how sound travels through the appliance.

A noise that once pointed clearly to a source may later seem to come from somewhere else. Pausing to account for age-related changes can explain why noise location shifts over time.

Wear reshapes the path before it reshapes the sound.

When Focusing on the Wrong Component Makes Things Worse

Misidentifying the source of a noise can lead to repeated attention on the wrong area. Adjustments or fixes may change how the sound is heard without addressing its origin.

This can increase confusion when the noise returns or changes character. Slowing down after an apparent improvement can help reassess whether the true source was ever addressed.

A quieter appliance is not always a corrected one.

Why Noises Often Signal Interaction, Not Failure

Many appliance noises result from interaction between parts rather than outright failure. This kind of interaction is often seen when a small appliance fault turns into a system failure rather than remaining isolated. Contact, friction, or resonance can create sound even when components remain functional.

Treating every noise as a sign of immediate failure can push decisions too quickly. Pausing to consider interaction can keep responses proportionate.

Noise often reflects relationship, not breakdown.

When Listening Less and Observing More Helps

Focusing too closely on sound can overshadow other signs. Changes in performance, consistency, or behavior may provide better context for interpreting noise.

Stepping back to observe the appliance as a whole can clarify what the noise represents. Doing less listening and more observing can slow assumptions.

Sound is one signal among many.

FAQ

Why does a noise sound like it comes from the wrong place?

Because sound travels through internal structures. Pausing to consider vibration paths can explain this mismatch.

Are loud noises always caused by major problems?

Not necessarily. Some noises come from interaction or resonance. Slowing down helps avoid overreaction.

Why does the noise change location over time?

Structural wear alters sound paths. Hesitating before assuming a new fault can provide context.

What’s the biggest mistake when diagnosing appliance noise?

Assuming the first perceived source is correct. When unsure, doing less and reassessing can prevent misdiagnosis.