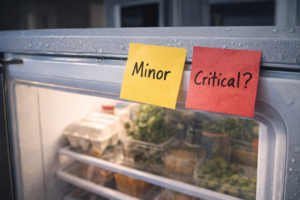

Refrigerator problems rarely announce themselves loudly at the beginning. A slight temperature change, a brief noise, or a small amount of moisture can feel easy to dismiss. Because the appliance often continues to run, these early signs can seem minor or temporary. Over time, however, many critical refrigerator failures begin this way, growing quietly while appearing manageable on the surface.

Why Early Signs Feel Insignificant

Refrigerators are expected to be stable, background appliances. When something feels slightly off but daily use is uninterrupted, it is natural to assume the issue is not serious. Small deviations are often explained away as normal variation or momentary imbalance. Temperature changes are one example of early signals that can reflect deeper internal failure.

This reaction is understandable, but it can reduce attentiveness. Early signs are often subtle precisely because systems are still compensating. Slowing down instead of minimizing these changes can help distinguish between harmless variation and the beginning of a larger shift.

The Role of Gradual Change

Most refrigerator systems degrade gradually rather than abruptly. Internal components adjust to wear by working harder or less efficiently. These adjustments can mask deterioration, keeping performance within an acceptable range for a time.

Because change is incremental, it can blend into normal operation. What feels like a small issue today may be part of a pattern that only becomes clear later. Gradual changes often carry hidden cost long before they become urgent.

Pausing to notice whether changes persist or repeat can be more informative than reacting to a single moment.

How Compensation Hides Problems

Refrigerators are designed with tolerance built in. When one part begins to underperform, others often compensate. Cooling may still occur, but unevenly or with more effort. This compensation can keep food cold while concealing strain inside the system.

The downside of compensation is that it delays clarity. By the time compensation fails, the underlying issue may be more advanced. Choosing restraint when things seem slightly off can interrupt this cycle before the problem escalates.

Why Small Issues Are Easier to Ignore

Minor problems fit easily into daily routines. A little condensation can be wiped up. Small amounts of water are often dismissed even when they indicate internal damage.

A brief noise can be overlooked. A temperature fluctuation can be adjusted for mentally. Each response reduces immediate discomfort without requiring reassessment.

Over time, this normalization can lower sensitivity to change. What once felt unusual becomes familiar. Stepping back when small issues recur can prevent normalization from turning into complacency.

The Pattern of Escalation

Critical refrigerator failures often follow a recognizable pattern. First, small inconsistencies appear. Then, those inconsistencies become more frequent or harder to explain. Finally, a threshold is crossed where the appliance can no longer compensate.

The early stages are the easiest to miss because nothing forces attention. Waiting for a clear failure often means waiting until options are fewer. Allowing early uncertainty to matter can preserve flexibility later.

Why “It’s Still Working” Can Be Misleading

A refrigerator that still runs creates reassurance. Lights turn on, the compressor cycles, and food feels cold enough. These signals suggest normal operation, even when internal conditions are changing.

Function alone does not reflect system health. Performance can remain acceptable while reliability declines. When confidence rests solely on outward function, slowing down to question that standard can prevent overconfidence.

Small Problems and Structural Stress

What appears small on the outside can reflect stress inside the appliance. Slight leaks, intermittent cooling, or unusual sounds may indicate internal pathways or components losing alignment. These changes rarely reverse on their own.

Because structural stress develops quietly, it often feels less urgent than visible damage. Choosing to pause rather than push through uncertainty can reduce the chance of turning manageable stress into irreversible damage.

The Cost of Delayed Attention

Delaying attention does not always cause immediate harm, but it increases uncertainty. Continued use under unclear conditions can allow problems to spread or compound. By the time an issue becomes unmistakable, it may involve more systems than it did initially.

This does not mean every small issue must be treated as critical. It means patterns deserve respect. Doing less while observing more can limit escalation without forcing premature conclusions.

When Small Becomes Critical

The transition from small to critical often feels sudden in hindsight. In reality, it is usually the result of accumulated changes reaching a tipping point. Because the buildup was quiet, the final shift can feel unexpected.

Recognizing that critical problems often have quiet beginnings can change how early signs are treated. Allowing space for caution early on can reduce the shock of later failure.

Choosing Awareness Over Alarm

Awareness does not require urgency or fear. It requires openness to the idea that small signs may matter more over time. This mindset encourages observation rather than immediate action.

Choosing awareness over alarm helps maintain balance. It allows early signs to be noticed without escalating stress. Sometimes the most effective response to a small issue is simply to slow down and watch what happens next.

FAQ

Are small refrigerator problems always a sign of something serious?

No. Many small issues resolve or remain minor. The concern grows when patterns persist or expand.

Why do problems seem to worsen suddenly?

They often build gradually and become visible only after compensation fails.

Is it safe to ignore minor issues if the refrigerator still works?

It can be, but continued uncertainty increases risk. Pausing and observing can reduce that risk.

How can escalation be recognized early?

By noticing repetition, inconsistency, and changes that do not clearly resolve. Slowing down can make these patterns easier to see.